2205 duplex stainless steel standard number: ASTM A240/A240M--01 Duplex stainless steel 2205 alloy is a composite stainless steel composed of 22% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy. It has high strength, good impact toughness and good overall and local stress corrosion resistance.

The yield strength of 2205 duplex stainless steel is more than double that of ordinary austenitic stainless steel, which allows designers to reduce weight when designing products. Advantages: high yield strength, sufficient toughness; excellent resistance to stress corrosion cracking; extremely high corrosion resistance; good local corrosion resistance

Application areas: pressure vessels, high pressure storage tanks, high pressure pipelines, heat exchangers, food processing equipment, oil and gas pipelines, sewage treatment systems, pulp and paper industry classifiers, bleaching equipment, etc.

|

Grade |

2205 duplex stainless steel |

|||

|

Product |

Stainless Steel Plate/Sheet |

Stainless Steel Coil |

Stainless Steel Pipe/Tube |

Stainless Steel Selt/Strip |

|

Thickness |

0.3-100mm |

0.3-16mm |

0.3-60mm |

0.05-16mm |

|

Width |

1000-3000mm |

1000-3000mm |

6-2000mm |

10-2000mm |

|

Length |

2000*10000mm |

Ton |

1000*6000mm |

Ton |

|

Surface |

NO.1, NO.2D, NO.2B, BA, NO.3, NO.4, NO.7, NO.8, HL, 6K, 8K etc. |

|||

|

Services |

Product thickness, size and surface can be provided upon request |

|||

|

MOQ |

1 Ton |

3 Ton |

By size |

1 Ton |

|

Certified |

ISO, SGS, BV, CE etc |

|||

|

Standard |

ASTM, AISI, SUS, JIS, EN, DIN, BS, GB etc |

|||

|

Payment method |

L/C or T/T. |

|||

|

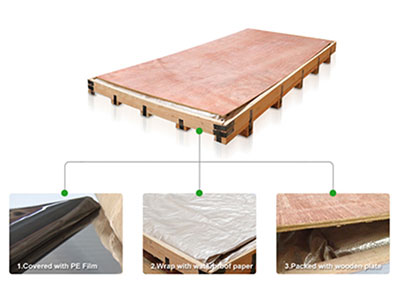

Package |

Waterproof paper + metal tray + angle steel protection + steel belt or as required. |

|||

|

The internal dimensions of the container are as follows: |

||||

|

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(height) about 24-26CBM, 23MTS |

||||

|

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(height) about 54CBM, 27MTS |

||||

|

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(height) about 68CBM,27MTS |

||||

|

Application field |

Food industry: kitchen equipment, food processing equipment, refrigeration equipment, etc. |

|||

|

Transportation equipment: railways, automobiles, ships, yachts, lighthouses, etc. |

||||

|

Storage equipment: oil storage tanks, water storage tanks, sinks, etc. |

||||

|

Construction industry: tunnels, bridge decks, roofs, high and low buildings, water pipes, etc. |

||||

|

Brewing: wine tanks, beer tanks, wine storage tanks, etc. |

||||

|

Others: drying equipment, granulator, conveyor, conveyor, mixer, etc. |

||||

|

Label |

There are no fixed sizes of stainless steel products only common sizes. All grades, sizes, thicknesses and surfaces can also be custom cut on request. |

|||

Chemical composition:

| Grade |

Chemical composition |

||||||||

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

N |

|

|

2205 |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.040 |

≤0.030 |

4.50-6.50 |

21.00-24.00 |

2.50-3.50 |

0.08-0.20 |

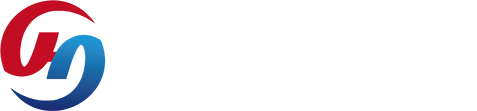

Surface:

|

Surface Finish |

Characteristics |

Definiton |

Application |

|

NO.1 |

Silver, matt |

Finished by hot-rolling, annealing and pickling characterized by white pickled surface |

Applications without glossiness requirements |

|

NO.2D |

Silver |

The finishes after cold rolling, by annealing ,pickling or other equivalenttreatment |

Petrochemical equipment, auto parts. building materials, steel pipes etc. |

|

NO.2B |

Glossiness is stronger than No.2D |

The finish after cold rolling, by annealing pickling and with SKIN PASS process |

Almost all applications etc. |

|

NO.BA |

Glossiness As a mirror |

Cold rolled, bright annealed and skin-passed, theproduct have excellent brightness and good reflexivity like mirror |

Building materials, kitchenware etc. |

|

NO.3 |

Rough grinding |

Polished with abrasive meterial of grit#100-#120, have better brightness with discontinuous coarse stria |

Nterior and exterior decoration, elect onicproduct appearance, kitchen equipment etc. |

|

NO.4 |

Hairline grinding |

Polished with abrasive meterial of grit#100-#120, have better brightness with discontinuous coarse stria |

Bathtubs, food fittings, interior and exterior decor etc. |

|

NO.7 |

Close to mirror grinding |

Polished with abrasive meterial of grit#600 |

For art, for decoration etc. |

|

NO.8 |

Mirror grinding |

Polished with abrasive meterial of grit#800 |

Buildings, mirrors, decorations etc. |

|

HL |

Hairline grinding |

Polished with suitable abrasive meterial on the NO.4 finish and has continuous streaks |

Building interior and exterior decoration etc. |

Application field:

Steel tank

Heat Exchanger

Printing and dyeing facilities

Food processing equipment

Steam equipment

Transformer